Cam Pro Plus

Measurement System

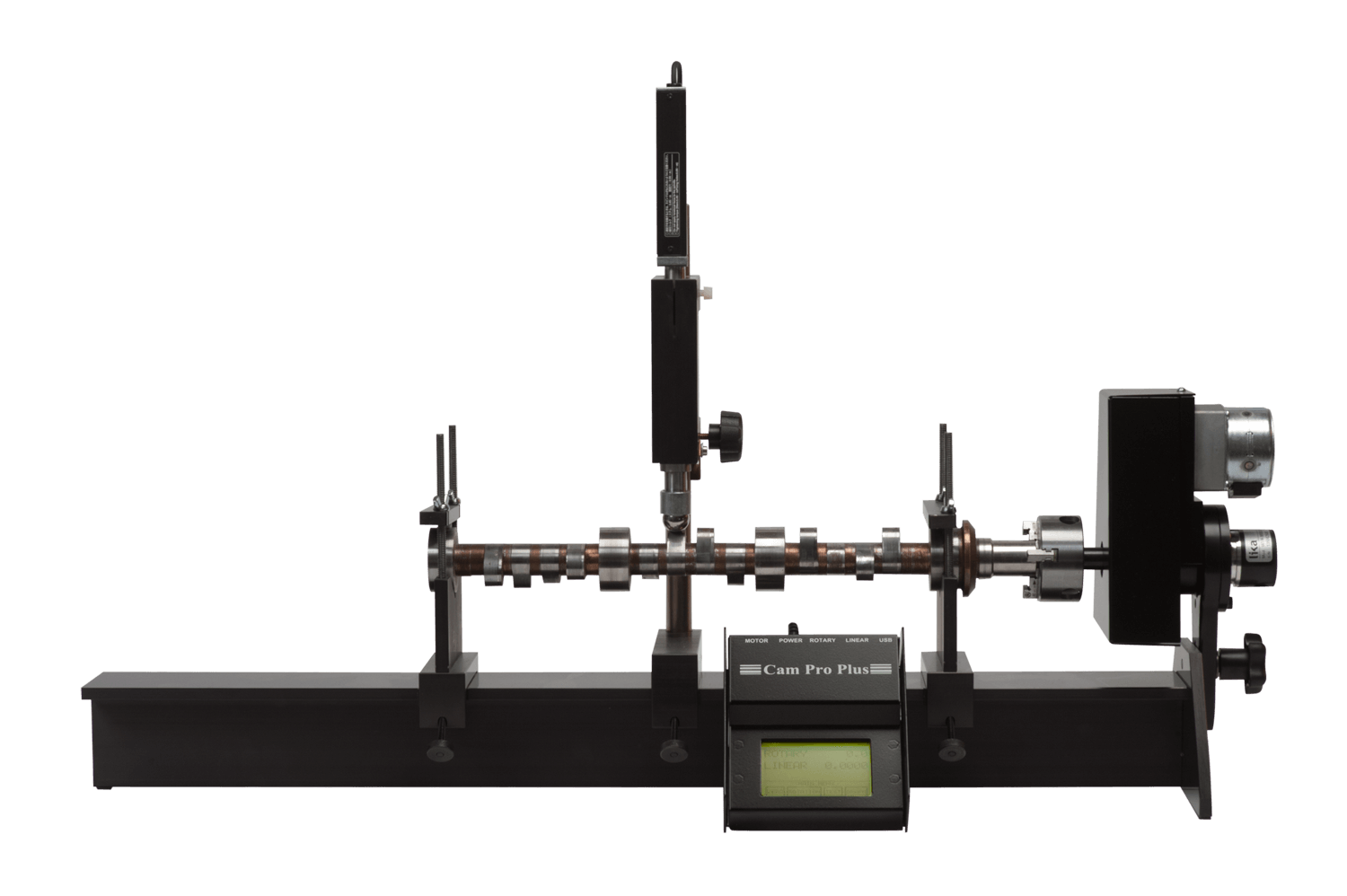

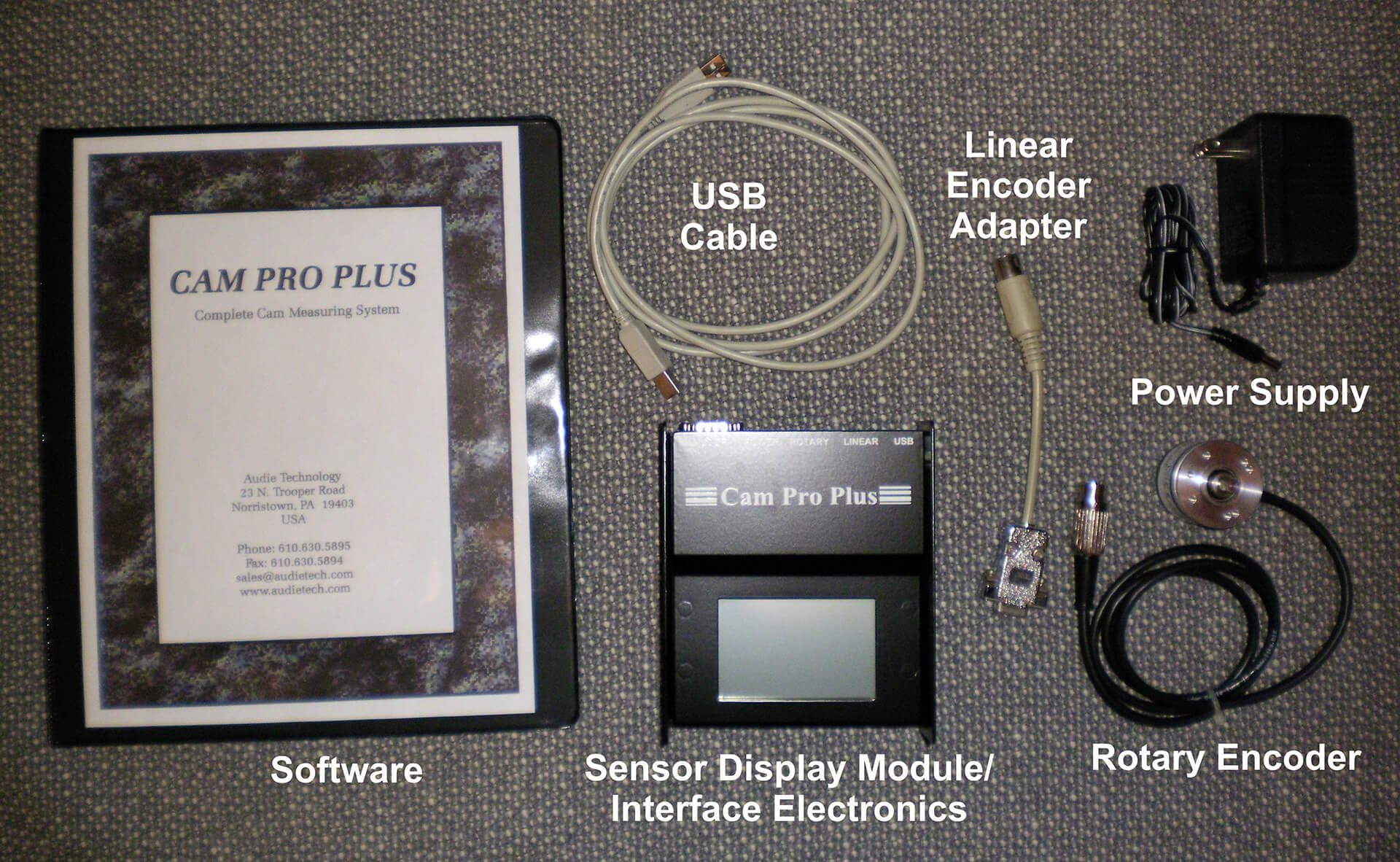

Cam Pro Plus is a software and sensor package for measuring and analyzing lifter and valve motion profiles. This is also a good tool for measuring duration, opening, closing, centerline, lobe separation, and cam factor. It features easy to use software and accurate sensors. Cams can be measured on its test stand or installed in the engine. Several software option packages are available for advanced and specialized analysis.

Why You Need Cam Pro Plus

- Save the time spent trying to tune an engine with a bad cam. Check cams before you install them to verify that they match the cam card.

- Simplify cam degreeing. Cam Pro Plus tells you what TDC lift is at any amount of advance or retard. You need only to find TDC and adjust the cam to produce that lift. There’s no need to mess with degree wheels.

- Analyze lash and rocker changes before you make them. It is much more efficient to predict the effect of lash and rocker ratio changes on valve duration and the timing of valve opening and closing events than to make changes by the trial and error method.

- Verify the cam grind. Verify that specially made cams match what you ordered.

Analyze cams with missing manufacturer part numbers. It is common practice to grind off identifying marks. Now you can analyze the camshaft without knowing its part number. - Compare cams on the basis of their total profiles. Duration and total lift numbers from a catalog do not tell you the whole story.

Study your camshafts to learn what makes a good cam for your engines. There is no substitute for knowledge.

Simplified Visual Setup

Cam Pro Plus simplifies cam measurement setup. Test setup is easy with its universal cam diagram system. Just match the diagram to the layout of the lobes on your cam, and number the cylinders on the cylinder map. It even comes with pre-defined setups for common engines. The result is an easy setup that doesn’t sacrifice flexibility.

Easy Installation

Installation is a snap. There are no add-in cards. Just plug the sensor module into a USB port on your computer.

Accurate Sensors

Cam Pro Plus is accurate. The standard rotary sensor measures to 1/10 degree. The standard linear sensor can resolve 1 micron (0.00004 inches). Available upgrade sensors boost resolution to 1/40 degree and 1/10 micron.

Powerful, Flexible, Easy to Use

Cam Pro Plus can handle up to 4 cams and 16 cylinders per engine, multi-valve engines, over 50 lobes per cam, overhead and push rod cams, and V and inline engines. You can measure in the engine or on a test stand. The rotary motion sensor can go on the cam or the crankshaft. You can measure valve or lifter motion. Measure a few or as many lobes as you want.

Measure on Stand

Measuring a cam on a test stand is not as easy as it looks. All the details of engine geometry that are not duplicated on the stand must be compensated by the software. The challenge is making the program flexible enough to handle all kinds of engines while keeping it clear enough to avoid errors in data entry. Cam Pro Plus meets the challenge with easy to use setup diagrams. Once defined, each engine geometry is stored in its own file, ready to be recalled and used without repeating the setup entries. Cam Pro Plus comes with several common engine geometries to get you started. Use them as guides to define any engine.

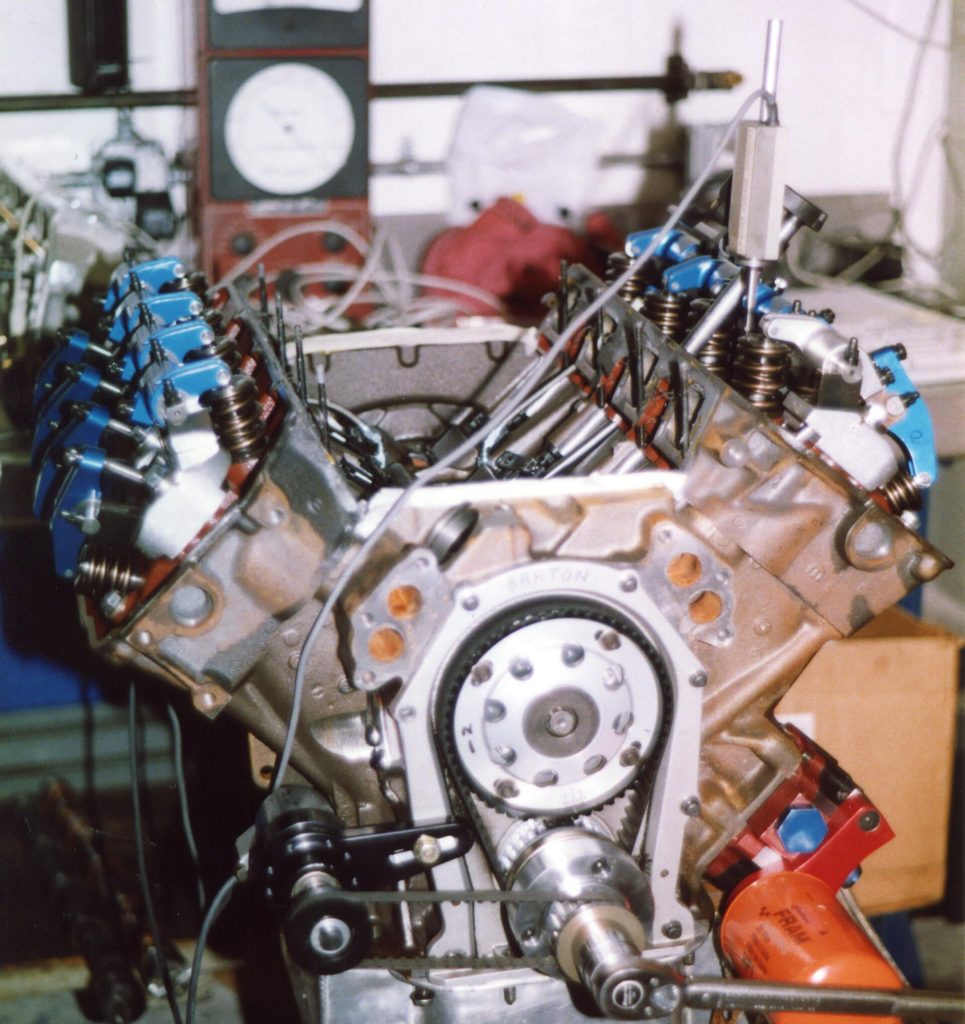

Measure in the engine!

Measuring cams on a stand is great – it lets you check a cam before you use it. But it has its limitations: it can’t detect misaligned lifter bores, there’s no way to measure lobe separation in multi-cam engines, and for engines with unusual valve trains (for example, variable ratio swing arm followers) it makes no sense at all. That’s why Cam Pro Plus lets you measure cams in the engine. Of course it’s flexible. You can measure follower or valve motion. And while our standard hardware drives the rotary encoder off the crankshaft, with your own hardware you can drive it off the cam.

Remote Operation

With Cam Pro Plus’ sensor module you don’t have to move your computer next to the engine. You can do a complete test from the sensor module. And since the sensor module displays sensor positions you can use it with or without the computer as a digital degree wheel. This is very handy for checking the timing of motorcycle engines without removing the engine from the frame so that a degree wheel can be attached.

Powerful Analysis Graphics

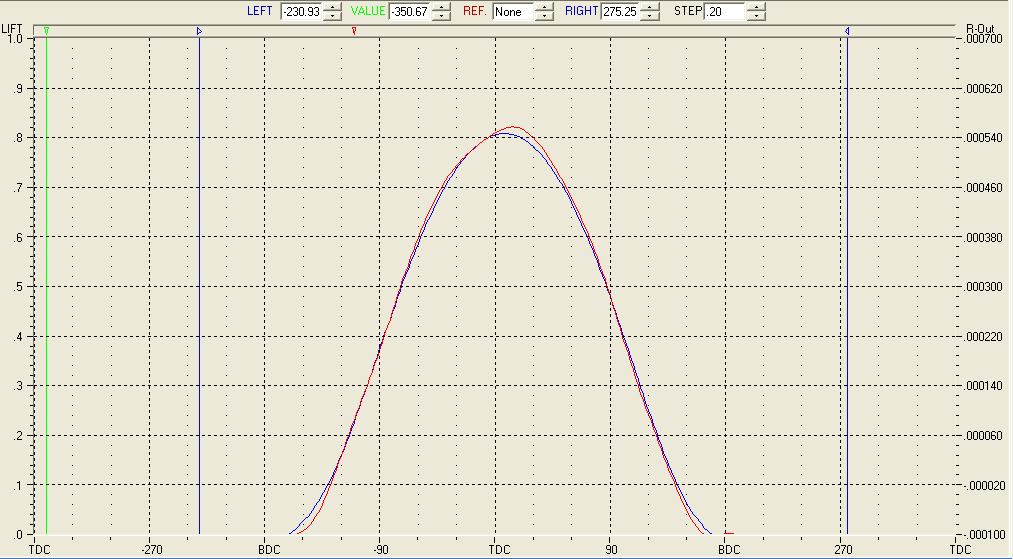

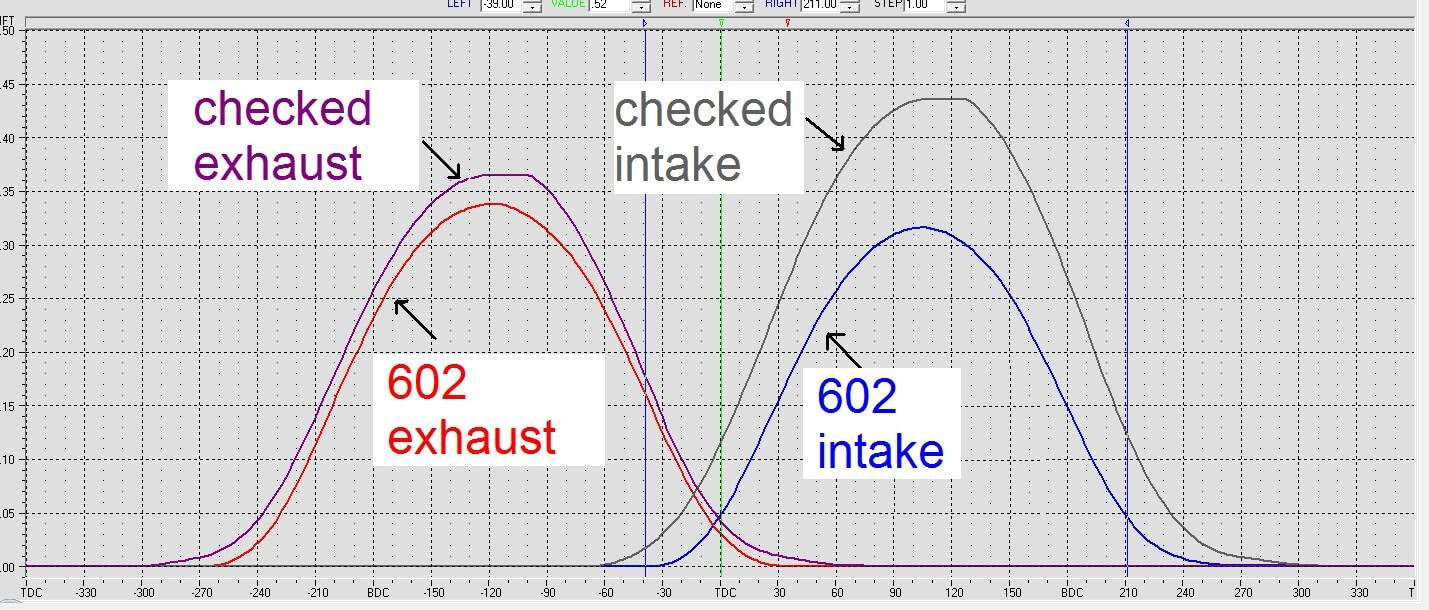

Powerful graphics in Cam Pro Plus make analysis quick and easy. You can overlay motion, velocity, acceleration, and jerk curves for both follower and valve motion. Add or remove curves or lobes with a single keystroke. Multilevel zoom aids inspection of fine details. Cam Pro Plus makes it easy to play “what if”. Base circle runout, valve lash, and rocker ratio can be adjusted individually for each lobe. Lobe centerlines can be shifted to any position. You can You can even use an intake lobe as an exhaust lobe.

Tech Inspection

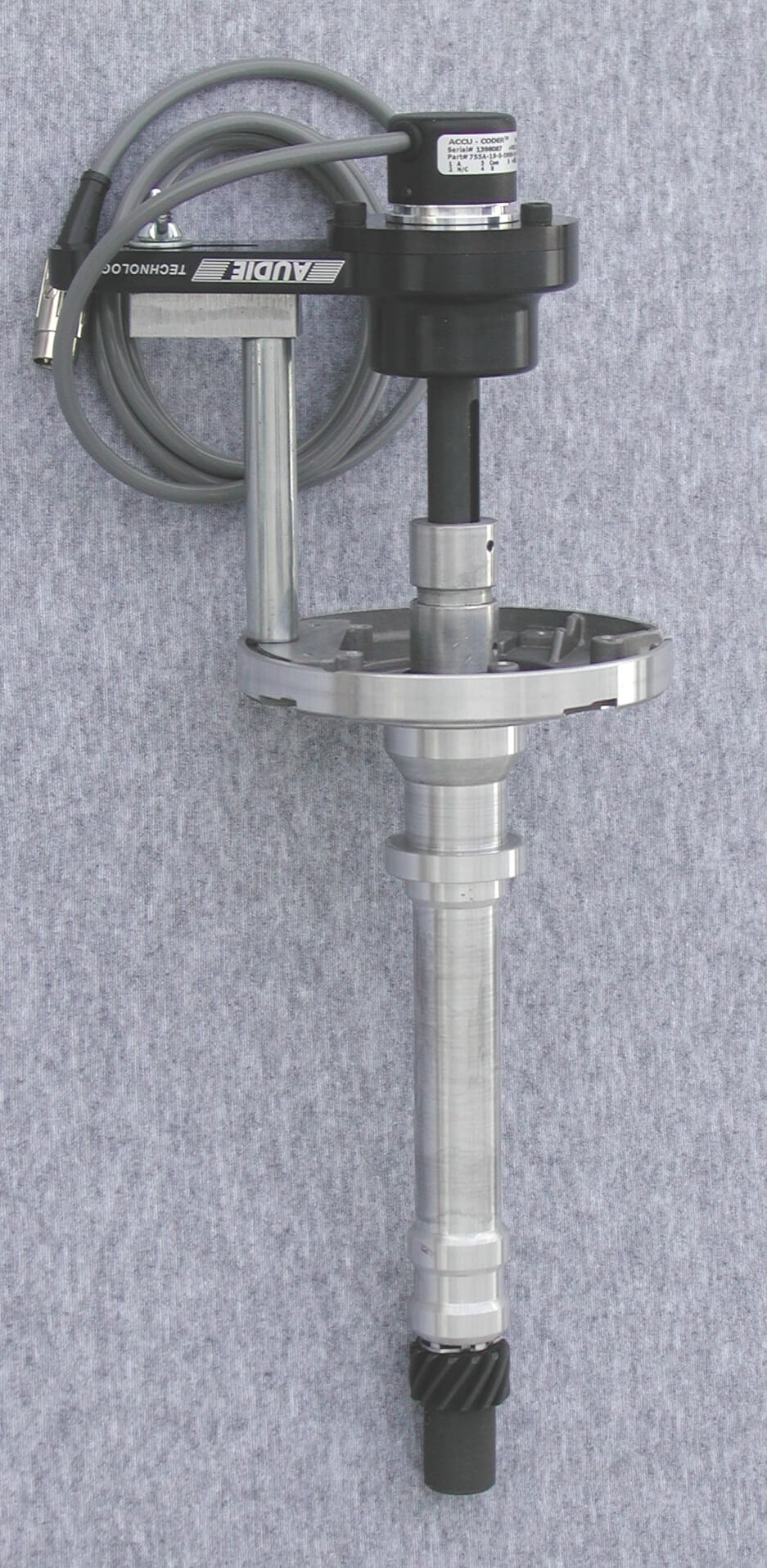

Tech inspecting camshafts is now faster, easier, and more accurate. No more fumbling with a degree wheel and checking only three points on a cam lobe. Just install the Cam Pro Plus on the engine with the tech distributor, and the linear sensor in place of your old dial indicator and you can check the cam in just minutes. Measure duration, opening, closing, centerline, and lobe separation, of crate engines or cam restricted classes. The rotary sensor measures to 1/10 degree. The linear sensor measures to 1 micron (0.00004 inches). And, unlike lesser quality systems, the measeurements are accurate and repeatable.

With this accuracy there is NO room for cheating. Ask any engine builder, there is no ‘getting around’ this. It can be adapted to most engines, not just Chevy’s. Installation is simple, just plug the remote interface module into the serial port on the back of your computer.

It’s no wonder that tracks using this system are experiencing growth. You’ll find more racers at the track when racers know that they will get a fair race. When one or two cheaters no longer win every week, you get more racers. We have even had racers buy this system for their track because it is more effective and less expensive than a protest!

Cam Pro Plus software has a special Tech inspector mode. It gives you the simplicity you want and the detailed information you need. Powerful graphics make analysis quick and easy. When you overlay ‘just measured’ lobes on previously measured baseline ‘legal’ lobes, you have a picture that anyone can understand and no one can argue with. It only takes a click to add or remove lobes. Multi-level zoom aids inspection of fine details.

Options

Easy Cam Software Option

This option allows Cam Pro Plus software to be used with the Andrews Products Easy Cam hardware. It also includes routines for importing Easy Cam files.

File Conversion Software Option

The file conversion option will convert Cam Pro Plus, S96, and Doctor Doctor files to Cam Pro Plus files. Standard Cam Doctor files may also be converted to Cam Pro Plus files, but the centerlines may not be correct. The option will also convert Cam Pro Plus files to Doctor Doctor, S96, or 4StHead files.

Keyboard Entry/Edit Software Option

The keyboard entry/edit option creates and edits Cam Pro Plus data files from keyboard entered lift data. Both keyboard entered and measured data files can be edited.

Open/Close Report Software Option

The Open-Close Data report uses a format commonly used by FISA (a European race sanctioning body) for cam specs. This format lists the lift for the opening half and the closing half side by side at a regular angle spacing.

Raw Data ASCII Output Software Option

The Raw Data Output option creates an ASCII file that contains the raw measurement data at full sensor resolution. CPP files always have data at 1 cam degree spacing. The sensor always measures at a smaller spacing. A simple CNC format is also possible with this option.

Runout & Deviation Software Option

This option combines two features that are of special interest to camshaft manufacturers. The runout feature corrects for shaft runout. It does this by measuring the journals to determine the runout, and then correcting the lobes when they are measured. The deviation feature compares lobes to a reference lobe, and generates a report that shows the angular and lift deviation.

Spintron Software Option

This option lets you work with data from Spintron csv files. Results from multiple RPM’s can be graphed simultaneously. Standard Cam Pro Plus files can be viewed together with Spintron files.

In this Cam Pro Plus graph the blue curve is 2500 RPM, the red one is 9600 RPM. Notice the reduced duration, probably due to flexing in the valve train. Examination of other RPM’s from the same test shows a pattern of reducing duration as RPM rises. Valve float is clearly visible in the 9600 RPM curve. There is also a hint of valve bounce upon closing.

Tech Inspection Distributor

Valve Train Software Option

This option compensates for overhead valve trains that have pivoting followers. It handles both cam on rocker arm (CORA), and finger followers. The option can also convert lift data measured with one diameter roller follower to what it would be if a different diameter roller were used.

Other Options

The standard options described above were all developed in response to customer needs. If you have special needs, please let us know.

Cam Doctor Upgrade

Over the years we have upgraded dozens of Cam Doctors. In a typical Cam Doctor upgrade:

- The stand, follower, linear encoder, and magnetic mount for the rotary encoder are re-used.

- The software and interface electronics are replaced.

- The rotary encoder is replaced, unless it is a Heidenhain brand encoder.

The Cam Pro Plus electronics interface to your computer via the computer’s COM port. The Cam Doctor’s special card that plugs into your computer is abandoned.

Universal Cam Adapter for Cam Pro Plus

The Cam Pro Plus stand has always used an adapter to connect the rotary encoder to the end of the camshaft. Since these adapters must fit the end of the camshaft, most Cam Pro Plus owners have needed a variety of adapters to measure all of the different camshafts they use.

The Cam Pro Plus stand has always used an adapter to connect the rotary encoder to the end of the camshaft. Since these adapters must fit the end of the camshaft, most Cam Pro Plus owners have needed a variety of adapters to measure all of the different camshafts they use.

Making these adapters, while not difficult, can be inconvenient. We have now developed a universal cam adapter. The universal adapter is a miniature 3 jaw lathe chuck which has been adapted to fit the Cam Pro Plus rotary encoder assembly.

Our testing has shown that the universal adapter yields results comparable to the standard adapter. The only exception was a variation of .0002 or .0003 inches in base circle runout. The variation seems to be related to the placement of the chuck’s jaws on the camshaft journal. For most Cam Pro Plus owners this is an acceptable trade-off to gain the universality. Those who can not accept this (mostly camshaft manufacturers) can still use the standard adapters.

The universal adapter costs less when ordered with a Cam Pro Plus stand, because some of it’s cost is offset by the cost of the standard adapter (that normally comes with a stand) which it replaces.

Photos

Owners

Camshaft Manufacturers that Use Cam Pro Plus (Partial List)

Bordeaux Dyno Cams

Boubis Cams

Brian Crower, Inc.

Bullet Racing Cams

Cam Motion

Cam Tech – Australia

Camcraft Performance Cams

Camshaft Engineering Co.

Camshaft Machine

Colt Cams

Crane Cams

Crower Cams

Demos Cams

Dougherty Racing Cams

Elgin Cams

Erson Cams

ESTAS – Germany

Howards Cams

Huggins Cams

Hyperformance Camshaft

Integral Cams

Kent Cams – England

Kelford Cams – New Zealand

Kiwi Cams Ltd.

Lunati Cams

Megacycle Cams

Precision Cams

Schneider Racing Cams

Spiros Cams

Sure Cam

Universal Crankshaft

Wade Camshaft

Web Cam

Schools that Use Cam Pro Plus (Partial List)

Central Michigan University

Citrus Community College

Cork Institute of Technology

Cypress College

Educacion Tecnica 5 Temperley

Ferris State University

Ingram State College

Mankato State University Mondello Technical School

Nashville Auto-Diesel College

Rosemount High School

School of Automotive Machinists

Southwest Research Institute

U.T.N. La Plata

Universal Technical Institute

University of Northwestern Ohio

Famous Owners of Cam Pro Plus (Partial List)

Air Flow Specialties

AJ Foyt Racing

AMA Pro Racing

American Car Service

American Harley Davidson

American Race Trucks

Andy Petree Racing

Arctic Cat

ASA Late Models

Bahari Racing

Bill Davis Racing

Bill Mitchell Racing Products

Bill Mann Performance

Borge Warner Morse TEC

Budweiser King Racing

Buell Motorcycle Co.

Carl McQuillen Racing Engines

Championship Auto Racing

Chev Offroad & Marine Engines

Chevron Texaco

Chip Ganassi Racing

Competition Proven

Cosworth Racing, Inc.

CV Products

DNE Motorsports

Eaton Corp.

Ed Pink Racing Engines

Enders Race Engines

French Grimes Race Systems

Furniture Row Racer

Gas Gas Motos

Gaerte Engines

Geoff Bodine Racing

Harley-Davidson

Hasselgren Racing Engines

Hendrick Motorsports

Honda Performance Development

Hutter Racing

Indy Lights Panamericana

Jasper Motorsports

JEGS Racing

Jenkins Competition

Jesel Valve Trains, Inc.

Jim Grubbs Motorsports

Joe Amato Racing

Joe Gibbs Racing

Joe Perez Racing Engines

John Force Racing

Kammer & Kammer Enterprises

Kohler Co.

Kroyer Racing Engines

Lewis Automotive

Lingenfelter Engineering

Lotus Cars, Ltd.

MAHLE Clevite Inc.

Menard Competition Technologies

Mercury High Performance

Morgan McClure Motorsports

National Late Model Series

Paul Pfaff Racing Engines

Penske – Jasper

Porsche Motorsorts NA

Port City Engines

Precision Engine Machine Co.

R & R Cycle

Ray Price Harley Davidson, Inc.

Rectificacion Balestrini

Reher & Morrison Racing

Renault – England

Robert Elliot Racing Engines

Robert Yates Racing

Roger Taylor Racing

Rousch Technologies

Royal Irish Auto Club

SCCA

Slawko Racing Heads

Solution F

Southern National Speedway

Stone Brothers Racing

Summit Racing Equipment

Sunbelt Performance Engines

Swindon Racing Engines

T & N Enterprises

Team Amick Motorsports

Team Menard

Toyota Motor Sport Division

Toyota Racing Development

V8 Supercars

Vee Two

Westech Performance Group

Yamaha Motor Corp.

Cam Doctor Owners that upgraded to Cam Pro Plus (Partial List)

Badgerland Machine

BCI Performance Warehouse

Bertil Racing Engines

Bill Mann Performance

Blueprint Racing Engines

Bob Lambeck Enterprises

Butler Engines

Caldwell Development

Camcraft Performance Cams

Camshaft Engineering Co.

Central Cylinder Service

Christman & Mullins Racing

Crane Cams

Crower Cams

Dart Machine – Canada

Daves Performance Engineering

Dick Johnson Racing

Dougherty Racing Cams

EC Distributing

Elan Power Products

Ernie Elliott, Inc.

Exclusive Motorcars

Fiat R & D – USA & Italy

Grooms Engines

Hasselgren Racing Engines

Holton Automotive

Hondata

Hypermax Engineering, Inc.

Induction Research

Jenkins Competition

John Sidney Racing

Leydon Restorations Limited

Lewis Racing Engines

MAHLE Clevite Inc.

Merkel Racing Engines

Motorcycle Performance Services

Murgic’s Automotive, Inc.

Patton Racing Engines

Paul Pfaff Racing Engines

PHP Racengines

Porsche Motorsorts NA

Precision Cams

RAM Aircraft

Rectificacion Balestrini

Reher & Morrison Racing

Righetti Enterprises

Roulunds Rotrex A/S

Schubeck Racing

SEM Powertrain

Shaver Racing Specialties

Signature Race Engines

Smith Brothers Racing

Specialty Engines

Speedway Engine Development

SPORTCAM

Sterling Performance

Sure Cam

T.O.E. Performance Products

Tomadur Engine Co.

Van der Linde Development

Wagner Repair & Performance

Watkins Engine Development

Web Cam, Inc.

Wesmar Racing Engines